Domestic Biogas Plant Construction Complete Guide 3rd Part

Domestic Biogas Plant Construction Complete Guide

In first part of Gobargas domestic biogas plant construction manual, we discussed it’s contents,

in detail, biogas introduction and development around the world. In 2nd part material required for a home biogas plant, benefits of gobar gas domestic biogas plant, its models, and components were discussed. In this part I will try to

describe its fixing, installation, this is a very important

step, it requires so much care and attention. I divide it into further parts so

that the reader can understand it easily.

- Size Selection of Biogas Plant Design

- Construction Site Selection

- Quality Standards 0f Construction Materials

- Plant Layout Of Bio Gas Plant

- Digging Of Pit

- Construction Of Digester

- Construction Of Dome (Gas Holder)

- Digester And Gas Holder Plastering

- Construction Of Manhole And Outlet

- Construction Of Inlet

- Pipeline And Appliances Fitting

- Construction of Compost Pits

Size Selection of Biogas Plant Design

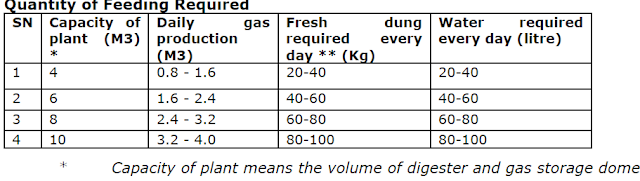

Size selection is the first important step for gobar gas/biogas plant construction. The size of a biogas

plant depends on the daily available quantity of feeding materials/gobar and biogas

requirements. In size selecting preference should be given to the availability of

dung, not the family size or gas demand.

On the basis of size,

fixed biogas plant design is divided into the following four types.

Size of fixed biogas the plant design can be classified on the basis of the quantity of fuelwood saved per

day and the availability of feeding material cattle dung etc.

Construction Site Selection

Construction site

selection is also an important step, the following factors must be kept in mind

during site selection.

- The site should be easy for construction works and guarantee plant safety

- There should be a site of minimum 10*15 feet for a family size biogas plant

- It should be away from the shade of tree or wall.

- It should be away from the water reservoir, and the water table should be a minimum of 15 feet.

- The temperature inside the digester should be 20-35°C, so avoid the damp and cool place, Sunny site is preferable.

- The kitchen should be near as possible.

Quality Standards 0f Construction Materials

Quality standards 0f

construction materials is of supreme importance for the proper functioning of the biodigester.

Thè materials required mainly are cement, sand, gravels, bricks, acrylic

emulsion paint, mild steel bars, main gas pipe, main gas valve, gas stove, gas

pressure gauge and mixing device.