Proper Construction of Domestic Biogas Plant

Domestic biogas plant construction complete guide is a detailed article that describes; all contents, introduction, material required, benefits and installation guidelines. In a proper construction of biogas plant. size, construction site selection and quality standards of construction materials construction of dome, gas holder and outlet tank are discussed in detail in the previous five articles. In this post-construction of the inlet tank, the fitting of pipelines and appliances will be discussed in detail.

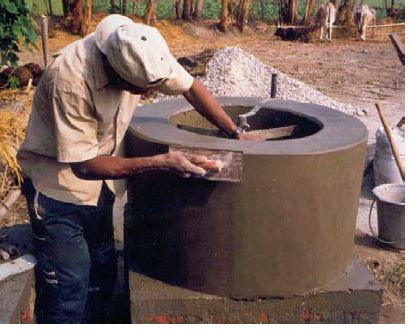

Construction Of Inlet Tank

As I said earlier, no we are moving towards proper construction of the biogas plant. In a proper construction of the biogas plant construction of the dome, gas holder and construction outlet tank are described earlier, now next step is the construction of the inlet tank. The main purpose of this tank is to mix dung and water for the preparation of desired 1:1 ratio paste.

First prepare a well rammed, hard and levelled surface and made a rectangular base for construction. The height of the base should be decided in such a manner that the floor of the inlet tank is at least 15 cm above the outlet overflow level.

After the construction of the base, the circular portion of the inlet tank is constructed. Before the construction of the round wall of the inlet, the arrangements should be made in the base for the mixing device. A pivot should be placed at the centre of the base of the inlet. A circular mark with the help of a thread or chord is made of 30 cm radius to decide the inner circumference of the tank.

The round wall of the inlet tank now should be constructed with the brick placed in a circular fashion following the mark already made. When the height of the circular pit reaches 45 cm, the iron bracket should be fixed to tighten the mixing device, if it is to be installed. The mixing device should be firmly attached to the structure, easy to operate, effective in the mixing process and rust-proof.

The inlet wall should be constructed up to 60 cm. In no case, the height of the inlet from the ground level should be more than 100 cm. The inside and outside of the tank are plastered with 1 part of cement to 3 parts of sand. The bottom of the tank must be at least 15 cm above the overflow level in the outlet wall.

Fitting Of Pipeline And Appliances

In the whole process, the biogas produced in the digester and stored in the gas holder is conveyed through the pipeline. If there is any sort of leakage in the laying and jointing of pipes then the desired results couldn’t be achieved.

Before starting laying pipes, first, make a layout on paper keeping in view a shorter route from the gas holder to the kitchen.

First of all the gas valve has to be fitted in position. Attention should be given not to have any fittings but rather a pipe nipple between the main gas pipe fitted in the dome and the main gas valve to avoid the risk of gas leakage. The joint between two pieces of PVC pipes should be properly sealed with sealing agents.

The biogas conveyed from the gasholder are saturated with water vapours. This water condenses when it comes in contact with the

walls of the pipe. If this condensed water is not drained regularly, it will ultimately clog the pipeline. Hence, a water outlet to drain the water has to be fitted in the pipeline. The position of the water drain should be vertically below the lowest point in the pipeline so that water will flow automatically by gravity to the outlet. Water should be drained periodically and therefore the location of the water outlet should be conveniently placed.

After laying of pipe from the dome to the kitchen, finally, connect gas stoves and lamps carefully. You can also install the pressure gauge. A gas pressure gauge has to be fixed near the point of application of the gas.

When gas production starts, there is a need to regularly check the leakage of joints and valves by applying a thick soap-water solution. If there is leakage, the foam applied to the joints will either move or break. If so happens, the joints must be sealed properly.

Bio Gas Technology